This technical article is to explain and show how to solve the problem of abnormal temperature or temperature alarm of the coffee capsule filling machine.

I will list several situations that may occur, and explain the causes and solutions of the problems one by one, as well as showing real cases, that is, what our customers have met before.

The most common is that the temperature setting value has not been reached.

See pic above, this is OMRON temp display and controller, 177 means real temp and 180 is set by operator, now it is heating up to 180

“Up arrow and down arrow” which the two buttons on the far right, these two buttons indicate to increase or decrease the temperature setting value (adjust based on the characteristics of the actual product itself and the sealing result)

Machine couldn’t run until temperature reaches the setting value, so operator should better turn on the “heating” function firstly due to heating time is about 15 minutes.

Before it reaches the setting value, touch screen displays alarm like “temperature is abnormal”, please ignore it, it just hasn’t heated up to setting value yet. Hit button” STOP” when reach the setting value which means reset alarm, then press ”RUN” button, that’s done.

Another case is I have one customer met the problem that temperature always unstable, the temperature is randomly higher or lower than the setting value, pic is as below:

Operator should clean up the heat seal station, then check thermocouples connection if it is loose. When you confirm everything is good, we still have one way to solve, “RESET”

Turn off the “heating” on touch screen and wait temperature drops down to about 100 degrees, follow each step as video link below.

After you finish over steps, please turn on ”heating” on touch screen, and wait heating up to the setting value.

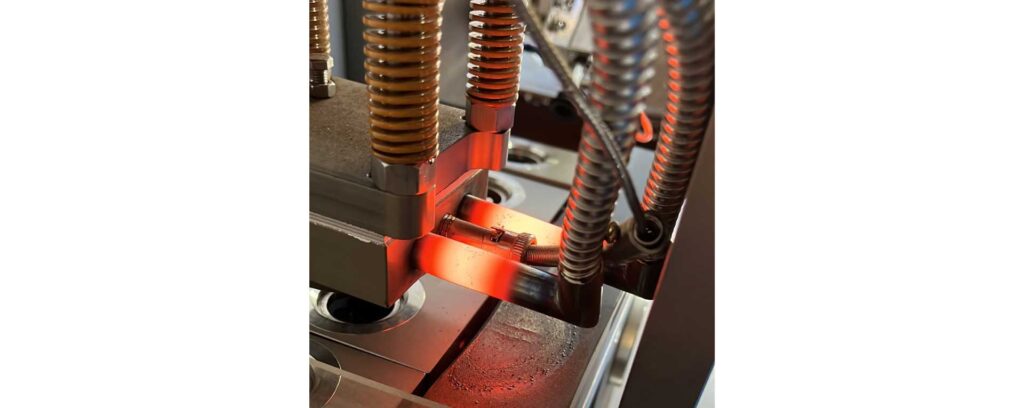

Still need to pay attention to the looseness of some wire connections or screws after the machine has been running for a long time, pic as below:

This is heat seal station, and heating tube is out of original position, clearly caused burn dents to the platform of the machine when heat sealer head goes down to seal capsule.

This is a typical case that screws are loose and couldn’t fix the heating tube after machine with a long term running. The operator just pushes the heating tube in and tight up the screws. The exact screws are as pic showed:

Conclusion

We just list a few situations, and it is possible that the temperature gauge cannot be displayed due to the damage of the temperature sensor, etc. We recommend that operator regularly check whether the wires and screws are loose, and regular cleaning will prolong the life of the machine.