Who invents K Cups?

In 1997, Green Mountain Coffee Roasters became the first roaster to offer coffee in Keurig “K-Cup” pods for the new Keurig single-cup brewing system, and in 1998 Keurig delivered its first brewing system, the B2000, Designed for the office. Distribution begins in New York and New England. The target market at the time was still office use, and Keurig wanted to capture part of Starbucks’ market. To satisfy brand loyalty and personal taste, Keurig discovered and recruited a variety of regionally recognized coffee brands that catered to every taste preference. The first of these is Green Mountain Coffee Roasters, and other licensors of the K-Cup line include Tully’s Coffee, Timothy’s World Coffee, Diedrich Coffee and Van Houtte, although Green Mountain is the dominant brand. Keurig has also partnered with a variety of well-known national coffee brands in the K-Cup variety, and in 2000 the company also expanded its beverage offerings in its K-Cup pods to include hot chocolate and a variety of teas. The brewers were large and connected to the office water supply.

What is K Cup filling machine?

As an automated production to implement filling ground coffee in empty kcup and seal it as a finished kcup can be worked by Keurig coffee machine.

Details of Workstation:

Drop Cup System

There are two different ways of loading cup, vertical loader and horizontal loader. Vertical loader as a regular loading kcups. If customer purchase large production and own a wide venue, horizontal loader would be better one. Manually push the kcups from pre-cup chute into the drop tube, the cup rubbing component separates a single kcup and falls into the mold plate, and the inner vacuum component grabs the bottom of the kcup and stably falls into the mold hole.

Kcup Detection

The kcup detection component device mainly detects whether there is a cup on the corresponding mold base through the photoelectric sensor installed above the cup. When there is no cup, the signal sent by the photoelectric sensor will be irradiated to the reflector through the mold base hole. It is passed to the servo motor, and then a stop command is issued, but we now make an update so that the production does not stop even if the cup is missing, when the mold base has no cup, all the functions behind the machine will not make any action on this hole.

Filling/Dosing System

Put simply, it has four parts:

- Servo Motor

- 2kg Hopper

- Precision Auger with agitator

- Compressed Fill-Head

Through the servo motor, the auger speed is accurately controlled to fill weight of coffee in a kcup. There is an agitator uses the auger as the axis and rotates in the opposite direction of the auger to keep the coffee average and prevent the coffee from becoming a bulk. And there is no need to consider the problem of aroma dispersal caused by oxidation, because we update brand new Nitrogen injection function, not only covering from empty kcup to filling, but also flush to hopper stay high quality coffee. After a hundred of tested and updated for residual oxygen, amazing to control it around 1%.

Tamper

Tamper mainly compresses the powder in the capsule through the cylinder, the rotary cylinder, the vacuum cylinder, the suction hood and its components, and sucks away the excess powder and dust on the edge of the capsule, greatly improve the effectiveness of the seal.

Lid Place

By placing the lid assembly, the Lid is drawn from the lid chamber and precisely placed on the top of the kcup, and the film will be positioned in the mold, which ensures the overlap of the lid and the cup.

Lid Detection

The lid detection station detects whether the lid is leaking through the photoelectric induction signal. If there is no lid on the capsule, the signal is transmitted to the servo motor, and the equipment alarms and stops and prompts operator “no lid”.

Seal

The heat-sealing station electrically heats the heater through the heating rod. After reaching the set temperature, under the movement of the heat-sealing cylinder and the top cup cylinder assembly, and at the same time under the positioning of the mold support and positioning assembly, the center of the K cup is connected to the heat. The head center is on the same line, then the lid and kcup are fused together. With our standard improve, we add one more heat-seal which twice seal guarantee better closure.

Outfeed

The outfeed station is to put the finished kcups on the slideway through the vacuum sucker or grabber and its cylinder assembly, then transfer it out.

Optional Function.

Auger Conveyor:

As a mechanical part to use conical bucket and pipe to convey the coffee into the machine hopper, bucket can contain 25kg ground but as it is mechanical drive so it guarantees better coffee quality.

Note: recommended for espresso coffee as coffee is fine grinding so by air conveyor will lost the great aroma while this auger system will keep the nice smell aroma of coffee so as to make good espresso capsule.

Check-Weigher:

To check each k cup within customer set range on interface, for example: coffee grams range 9.5gram-11.5g are defined good kcups and put on the belt to move to next packaging like Cartoner. Refuse unqualified pods to trash bin where it under the machine.

Flavor Pump System:

Can help you drop a precise flavor liquid (0.02-0.06ml) into every kcup when machine is running, usually as after coffee is filled, this could replace the old type mixing flavor powder tank for coffee and you don’t need to wash and worry flavor mixed because each pipe related to each flavor, which mean change pipe is change flavor.

Remote Control:

With internet connection (CABLE port prefer), customer at any location, USA or EURO or Africa as long as internet is connected, this can help customer a lot:

- Real Time Support Without Delay.

- Remote diagnose problems.

- Program upgrades online to reach customize or new functions.

- Machine running condition and regular maintenance remind.

Printer:

Link jet printer need to refill ink and black color so better for white kcups (not on black cups).

Cartoning Machine:

Auto open and form carton from magazine.Precision operation is not allowed to make mistakes, the unit uses YAHAMA Manipulator to complete the griping and placing of cups in box, as 12ct or 16ct and more packaging forms in different quantities.12ct as a reference: kcups are arranged in positive and reversed, there are two layers in total, each layer is 2*3.The sealing of the box is automated with Gluing System.

How do you make K Cups?

DIY to make a K Cup:

- Open the lid, and place your favorite ground coffee pack in the coffee chamber.

- If necessary, fill the water reservoir before brewing.

- Close the lid, place your mug on the drink plate, select your cup size and hit the button.

- Enjoy one perfect cup in less than a minute.

Machine to make a K Cup:

There is system for loading empty kcups to mould, then auger filler works and filling 12.5g ground regularly, then auto place a lid on the top of capsule, eventually seal it and put a finished kcup on the conveyor belt or drop it to a carton.

Our different models.

Basic Works Steps:

- Customized length Drop Tube as vertical loader or Customized Horizontal platform as grabber to place empty kcup with sensor inspection.

- Schneider servo motor cooperate with accuracy auger filler to working after UV lamps filter bacteria and two agitators make ground coffee always in an average and not in bulk condition.

- The cleaning system effectively collects dust and guarantees the subsequent sealing.

- Place lid to implement preliminary cover.

- Lid detection.

- First Heat-seal.

- Second Heat-Seal.

- Outfeed with Check-Weigher pass qualified one to customized conveyor belt and refuse bad ones.

- Nitrogen injection works continuously while the machine is running.

- Alarm system is convenient for operator for checking such as:More empty cups need to be required, coffee is not enough, please add more lids.

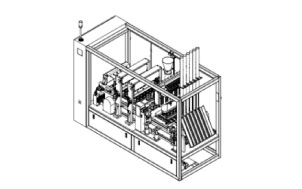

CPR4501 Rotary K Cup Filling and Sealing Machine:

2400-3300 Cups/H with each pod contain 3-20g ±0.2gram. Nitrogen Injection with whole production.UV light and Anti-Static Device as a Standard Part.

If you wonder more information, please click here.

[table id=1 /]

CP4501 Linear Single Lane K Cup Packing Machine:

Constantly running for 2400-3000 Pods/H. Ideal budget for starting up Kcup business. A compacted dimension with high configuration.

If you wonder more information, please click here.

[table id=2 /]

CP5002 Linear Two Lane K Cup Filler and Sealer Machine:

Capacity is 4800-6000 kcups per hour. Suit for expanding production. Add one more heat-seal.

If you wonder more information, please click here.

[table id=3 /]

CP50 Series Linear Multi-Lane K Cup Filling and Packaging Machine:

Upgraded speed up to 50 cycle each lane per minute. Fully Stainless Steel 304 material with framework thicker and durable. All functional components are from high-end brands.

If you wonder more information, please click here.

[table id=5 /]

PB-F1 automated K Cup Cartoning packaging Machine:

Automated packaging line Flexible solution for various packaging specifications.

If you wonder more information, please click here.

[table id=6 /]

Basic Works Steps:

- A kcup platform to connect with equipment.

- A separator makes kcups divide into two columns.

- Flipper make kcups into positive one and reversed one.

- Open and form carton from carton magazine.

- Fixture fixed kcups as one group.

- Robot place groups of kcups into carton.

- Gluing system working on the top and bottom of carton to seal.

- Alarm system is convenient for operator for checking.

Detailed of K Cup equipment.

This equipment is highly integrated with machine, electricity and air, including mechanical device, PLC control system and pneumatic control system.

The mechanical device is completed under the synergy of electricity and gas, such as Kcup Loading (kcup grabbing, kcup topping), Coffee Filling, Coffee Pressing, Lid Suction, Heat Sealing, Kcup Outfeed, Transportation, etc. Among them, photoelectric detection devices are installed at the drop tube and loading, suction lid and kcup outlet to detect whether the kcup operates according to the set program.

The mechanical device of the whole machine can be divided into the following parts:

- Transmission Part.

- Horizontal Conveyor (kcups are inside a removable and adaptable mould).

- K Cup Detection Station.

- Filling Station.

- Tamper and Clean System (press powder and dust suction).

- Lid Place Station.

- Lid Inspection Station.

- Heat Sealing Station.

- K Cup Out Station.

The electronic control system consists of main motor, inverter, servo motor, servo driver, heating device, PLC (Schneider), Interface, photoelectric sensor, encoder, proximity switch and other electrical components. The electrical components of this equipment are highly integrated and have strong control capabilities. The application of the touch screen makes the operation of the equipment more convenient. The application of photoelectric sensors, encoders and proximity switches makes the mechanical and electrical integration of the machine perfectly reflected.

The pneumatic control system mainly controls and drives some actuators to complete the corresponding actions to simplify the mechanical structure. It is composed of pneumatic components such as throttle valve, connecting air pipe and a series of pipe joints. The pneumatic components of this equipment have high reliability and stable operation. Since the electrical system uses compressed air as the working medium for the transmission of energy and signals, in order to ensure the service life of the components of the pneumatic control system, please use dried compressed air.

We are willing to give two solutions of complete packaging to be chosen.

Two lane K Cup filler sealer connect with semi-automated cartoning machine:

Output is 8-10cartons per min.

Brief Intro:

- As you can see there is two customized conveyor belt for kcups with single unit motor to control. After checkweigher worked, great kcups are enter into these two tracks, we still equip sensor at the beginning of track that If kcups queue is too long, it will be detected and the K cup filler will automatically stop working immediately. One of track is receive positive kcups and another one receive reversed kcups by flipper working.

- Kcups forward to next step, design two custom fixtures to fit with kcup, and then release three for each track. The fixture with sensor will automatically push the kcup to the corresponding slot and fix it until the robot grabs it. YAHAMA Robot grab two times as a group which 6 kcups and put them into carton (carton is manual arranged in conveyor belt with fixed slot). Then repeat this procedure again as two layers. The difference of two procedures is final place that height of place a group. Need to figure it first layer and second layer. Then, the staff can pack carton.

Four lane K Cup packing machine connect with automated cartoning machine:

Output up 10-15 cartons per min.

Brief Intro:

- There is a wider platform to forward kcups already tested with checkweigher from K Cup production line, which mean these are qualified kcups.

- Firstly, the separator will divide them into two columns as two independently tracks, each track equips guided railings can effectively protect kcups forward in a correct direction without falling down that would cause a crowd.

- Rotated flipper has two grabbers inside and another two gap, kcups could go through and not to throw out due to specific speed, this grabber is designed to just catch the body of the kcup, and it rotates all the time, so that the positive kcup becomes upside down, so that one positive and one reverse advance alternately as a result of the hole with grabber and the hole without grabber work alternately. And two flippers work on two tracks to guarantee the requirement of output.

- When one positive and one reverse advance, they are arriving as a group of six kcups with a fixture worked. YAHAMA robot will locate and grip a group to carton, the carton is formed by opener working from carton magazine and tested mechanical parts. Then robot will accomplish the action again as a packaging solution of two layers (layers and columns depend on customer’s demand). Afterwards, belt would forward carton to be sealed for bottom and top thanks to gluing system.

- These cartons of kcups are finished and sold out eventually.

A brief summary of different models.

CPR4501 Rotary Model:

Entrance model speed up to 3300pods per hour. Flexible with different coffee capsules in a quick format with change-over mold. Brand new design with functional automated machine for Kcup packing.

CP linear K Cup Model:

Also be an entry-level machine speed up to 3000pods per hour, a compacted layout but with wide space for more optional features, machine with a UV lamp can make your products safer and more competitive.

CP Two lane K Cup Model:

Two lane as a medium model up to 6000pods per hour, this equipment is a start to help you expand your production capacity. The high output will not occupy the space of your factory.

CP Multi-lane K Cup Model:

Large output can up to 3000 single serve per hour each lane, we provide four lane, six lane, eight lane, even customer require 12 lane. Multi-lane machine suitable to cartoning machine as a complete line to figure out automatic solution.

PB-F1 K Cup cartoning machine:

As a secondary packaging to connect to Kcup capsule filling machine outfeed up to 13 cartons per min. Just one person to replenish carton in time and put it into magazine.

Model comparison.

Comparison to other K Cup filling machine in China

Output:

Our entry-level model can produce 2400-3000kcups per hour but others make 1500-2000kcups per hour.

More complete detection system:

We have four detection system for Kcup production. Which is Less kcup detection, missing kcup detection, coffee material detection, lid detection. But others just missing kcup system and lid detection.

Better system:

While our machinery is fully functional, more options can be added to achieve all customer requirements. The electrical system of our equipment is Schneider, pneumatic components are from SMC. But electrical system of others is from Omron, pneumatic components are from AirTac.

Safety considerations:

We create safe system with a door that an alarm connects to the door of machine, when you open this function by HMI, make door closed otherwise machine would alarm and stop running. Another thing is broadcast system for reminding operator if no coffee, no lid, no cup, it will report this information with a broadcast.

Service life:

With high quality components equipped and much experience building technology from Expak engineers, also promise to give 18 months for warranty time with our product. Normally factory just guarantee 12 months for their product.

Conclusion: CP series Kcup filling equipment gain advantages in many ways, whether it is a roaster who has just started the kcup business or a relatively mature kcup production line, who wants to expand and transform a fully automated packaging line, there is no doubt that our machines and solutions are the first choice.

Internal model comparison

CPR4501 VS CP4501:

As two entrance types with single lane, their output almost same, up to 3000 kcups per hour.

- Dimension: CPR4501 as a rotary one is a compacted machine than CP4501, if you have a space problem, then the CPR4501 may be a better choice.

- Variety for different pods: Many roaster owners who are just starting up the coffee capsule business, and want to make two or even three kinds of capsules on one machine, the CPR4501 may be more convenient to change molds due to its simplicity and fewer stations (12 stations on a rotary plate), you can spend less time to change the change-over mould than CP4501.

- More optional: The CP4501 model will win in more optional functions. Based on its more workstations and more open linear space, UV light, anti-static device, checkweigher, and the length of the customized body to meet more requirements, and a slight advantage in later maintenance. CPR4501 just have 8 workstations, and the space is relatively compact.

Conclusion: If you want the proper output, but also take into account the space problem and do more kinds of coffee capsule, you should choose CPR4501. If you consider add more functions and maintenance, CP4501 should be chosen.

CP5002 Two Lane VS CP Series Multi-Lane like CP5004 CP5006:

Output: CP5002 is actually a new platform as between single lane CP4501 and the multi-lane bigger machines. It is medium capacity type up to 100 kcups per minute, while it has all complete functions like the bigger CP5004 CP5006 machines. And multi-lane CP5004 CP5006 has over 200pcs or 300pcs per minute.

Secondary packaging: as CP5002 already has enough capacity, so it is necessary to connect with auto-cartoner to replace the hand packing kcups into paper cartons. For CP5002 we designed a special semi-auto solution, that is less expensive than the complete auto cartoner yet, it is still quite efficient way to handle 9 cartons per minute, as robot auto grab cups and load into cartons. And the cost is much lower and the footprint is also smaller.

While the higher models as CP5004 output a lot at 15cartons per minute, so the carton system is much bigger size and need enough workshop to place the connection belts and the cartoner is full auto as open and close by hot melt glue. And of course, this system is higher cost.

Here is the link you could watch.

And you have to use a total different carton type that is glue sealed and not the hand pack type cartons.

Conclusion: if you just enter the business or expand production, CP5002 is a great choice. But If you want to expand enough production, and with enough space and budget to do full auto complete auto line, CP Multi-lane connect with cartoner is deserve to be considered.

Comparison of EXPAK CP5006V K Cup filling machine with best European Italy made K Cup filling production.

Let’s help you compare European SR6 machine stands for European best kcup filling and sealing machine as example and compare with the challenger: China made EXPAK CP5006V kcup filling and sealing machine.

First let’s have a look of EXPAK CP5006V K Cup filler and sealer machine:

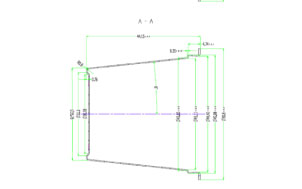

It is a compact machine with small size and controlled weight, and drive by mechanism shaft and gearbox system. length as 3000mm(9.85ft) width 1110mm(3.6ft), and height as extendable between 2000mm-3000mm (6.5ft-9.85ft), its weight is within 1500kg(3300lb).

The machine’s main components are all world first-class top brands as SMC for air system and Schneider for electric components.

Simple design and enough space so daily maintenance work is easy.

It is ready to fit standard, barrier, compostable and compostable barrier kcup or k-shot capsules and moreover with quick change over design to fit for different capsules like Nespresso or Dolce Gusto.

Capacity speed:

CP5006K machine has six lanes, each lane is able to produce 50 pcs kcups per minute, so total as 300pcs kcup per minute.

Main functions and features:

The process of its functions is complete as vertical loader infeed the kcups, check each lane cups ready, filling system to dose different products such as coffee, tea leaves or any soluble, standard equipped with high exchange nitrogen flush system, place lidding then dual sealer to seal the capsule twice, take out the finish kcups and place on the exit conveyor belt.

VERTICAL LOADER SYSTEM

Filler system is by precise auger system and drive by servo motor to reach accurate weight control, the accuracy is 0.1-0.2 g per cup.

A 10’’ touch screen could control the machine while temperature control is clearly listed just below.

The investment idea:

This complete machine is between USD60000-USD80000 based on different optional functions customer can add.

Delivery time:

As fast as 30 days.

What is required for a long-term production run and maintenance?

This machine requires electric and compressed air to run.

The electric power is 15kw and 220V usual North American standard power.

Compressed air is 30NM3 per hour at pressure 0.6-0.8Mpa.

Service as pre-sales and after-sales, customize for every customer.

As EXPAK is over ten years’ expence as China’s player, however, compare to European companies who have over 20 years or 30 years history, the younger is more open and flexible.

24hours a day always online for you.

offering packaging materials service if you need help at the beginning.

18months guarantee period for every machine.

Free maintenance trips in north America market.

EXPAK offer custom-built service for K Cup filling machines:

For example, we could offer multi-language service to put on the touch screen, which can make operator not necessary to have to know English and use a more friendly interface.

Even made voice alarm system to tell the operator by speaking which is very creative way in machines.

European SR6 kcup filler:

Let’s have a brief look of the SR6 machine from traditional premium machine:

Capacity speed:

SR serious is defined as medium production. It has 4 lane and 6 lane two models.

Each lane is max 60pcs per minute so SR6 as 6 lanes up to 360pcs per minute. (SR4 as 4 lanes up to 240pcs per minute).

Main functional features:

Main drive system is now as camshaft system, mechanical driven to each function station connected.

With a rotate touch screen of 15 inches panel, operator can easily watch the production and control the screen at same time.

Filling system is also auger type and dosed through an auger system driven by a Brushless motor.

Machine is prearrangement for nitrogen tunnels and in-line weighing system.

What is required for long-term kcup production use?

First, it eats a lot more, power consumption is 18-25kw, and compressed air 55NM3 per hour and nitrogen is 65-95NM3 per hour, that is really a lot!

The working station is very compact and the space is very narrow, so it is not friendly to be touched, and maintenance is being very difficult, the technician would not be easily to work on each station to fix it when problem happens. You need to prepare very skilled technical team to use the machine, which will be very difficult to find, as there are very few there to be hired yet it is huge expensive to keep them.

Machine size and investment ideas:

As this SR series nearly two times size of EXPAK CP5006 machine, and the weight as 3500-4800kg, customer have to ask for a professional 3rd party to unload and install it by a big forklift truck.

Come to the budget part, this kind of machine is the market most expensive products so it is normal price like USD500,000-800,000 cost, this is very big investment amount.

delivery time is longer, you have to give them enough time to make it so with a deposit paid, customer still need to wait like 6-12months to be shipped out from Europe.

Not with customized design allowed for customer different ideas, and not willing to offer packaging materials.

SUM UP:

Both machines are very good however they are different.

European machines are master piece but too expensive and require skilled technician.

EXPAK machine is smaller so as flexible to be placed anywhere, simpler structure and the wider space so easier for maintenance work, and it does not require skilled team to use it, Chinese team offer the friendly way to service all kinds customers and most important: the much lower price made it as a much smarter choice than the European machines to allow more potential customers to produce kcups and enter the kcup business.

FAQ of K Cup filler production.

Is it complicated to install the equipment?

- Quite easy to figure out. We could pack and fix integral filling machine with wooden box.

- When the machine arrives to your factory, you just need to install vacuum conveyor (for loading coffee granule), and connect to your compressor and Nitrogen generator with two pipes.

- We will offer circuit diagram to your electrician to wire or a socket method to plug in.

How about the Warranty and After-sales service?

- 18 months limited guarantee against BOL date as: broken parts be sent by international fast delivery total under seller’s cost.

- lifelong FREE supporting service including technical support, software updating, internet remote online support/debug etc. If buyer require installation service, that is available for us to dispatch our engineer to figure out.

- We will go abroad specially the US and Euro every year to participate in professional exhibitions about coffee, visit customers and solve problems, these are what we have been doing in order to provide customers with better services.

How to choose a great supplier for K Cup equipment?

- First of all, product quality is the foundation. Suppliers must have a stable and effective quality assurance system, as well as the equipment and processes required for specific production.

- The second is the configuration of the equipment, the brand of accessories, whether the functions are complete, and whether the operation is stable. For example, Expak’s kcup packaging line is equipped with the world’s leading brands.

- Certificate, whether there is a professional certificate, similar to CE, have you been to foreign countries to help customers deal with machine failures.

- In addition, it is necessary to focus on the service capabilities of suppliers, that is, pre-sales service and after-sales service. Whether the pre-sales service has deepened your understanding of Kcup equipment, and the after-sales service can quickly and professionally handle problems.

How to maintain the machine?

- check any stations that interfere with the moving belt, such as cup lifter, sealer station, make sure nothing would be inside and stuck the machine normal move cycle (every day before you start the machine).

- check the working status of pneumatic components, to ensure that the cylinder can run smoothly(1-2months).

- lubrication: add lubricating oil (every 1-2months); Apply grease to the drive chain(3-6months).

- calibrate the zero position of the each stationso the mold plate can be accurately positioned in center(3-6months).

- cleaning: use the air gun to blow off dust (every week) and deep clean to remove dust and coffee of bottom chains and drive system (every 6months).

- check the tightness of all screws and tighten them (every 6-12months).

- check the connection status of the electric circuit and the pneumatic circuit , remove dust and confirm no air leakage(every 6-12months).

How to place orders of machines?

- The most important is to confirm which kcup you want to use, which we will need to manufacture the machine to fit your cup and lid size. Samples is needed if the cups and lids are out of China such as made in USA, if you have more than one type of cups and want to be produced on one same machine, then we will require both samples and also the size drawing if possible.

- As business part, we would sign contract with all details listed and then make the Proforma invoice to proceed with payment operations as deposit..

- When a machine is finished, we will let you know and we will do a serious inspection, during the COVID as not convenient to visit so we also offer online video inspection to allow the customers to see the machine running though online video call then you could confirm all is approved and pay the balance and ship out.

- Besides wire payments we also offer platform such as Alibaba, the platform could help the customer to make sure money is safe, you can choose this way if you first cooperate with a new supplier.

How to know the shipping freight and time?

- Good news is we have partner is engage in freight agent. So you just choose which machine you are going to purchase. Then tell us port that you hope to ship to.

- We can get estimated price with dimension, weight of machine and your address from forwarder. For example:

- CP4501 Model ship to port New Work.

- Dimension:2250*960*2250mm, 4.9CBM, Weight: 750kg.

- From Shanghai to New York port. 250USD/CBM, 30days.

- Which mean 1250USD, 30days arrive New York.

How equipment can help business?

- The first thing that needs to be clarified is that the trend of advanced machinery is automation, and mechanical operations will increasingly replace manual operations.

- Let us see a reference from our product as a cartoning machine for kcups: Automated carton packaging line can make 15 cartons per min. but a person just finishes 6 cartons in a min. moreover, staff sometimes make mistakes, resulting in unqualified products or asking for leave to be absent from the factory, delaying production Therefore, in terms of labor cost and efficiency, automatic mechanization is undoubtedly the best choice.

How much coffee is packed in each K Cup?

- There are 10-12 grams (±0.2gram) of regular ground coffee in the average Single-Serve. If you pack soluble like chocolate, you can pack much more grams like 16grams. If you pack tea leaf for tea kcups, usually is 3-5grams is enough to make a cup of nice tea.

Can l make my own K Cups?

- Yes, it is quite easy to do a DIY Kcup, take an empty kcup with filter, put finely ground like 9-12gram in this single-serve, then choose a lid to seal.

Are K-Cups made in China?

- No. Final coffee kcups are packed in the states so as to have fresh roasted and ground coffee into every kcup, China only provides the packing machine equipment and the packaging materials. We offer the ready solution that allows different roaster could make his own coffee and pack into his own kcups.

What is the best grind of coffee for a Keurig?

- Medium to medium fine coffee grinds are the most popular choice for Kcup drinkers. Even many brands of coffee offer this coffee grind, or you can grind your own. A medium fine grind will be a bit thin in texture and tough like sand. This allows the water to flow quickly through the coffee grounds. However, with EXPAK special filter material, you could also do a fine grind that is very close to espresso grind, and it stills works fine in the kcups, this could allow the kcup producer being more flexible to use different grinding and with such finer ground, the kcup system also could brew out a much stronger coffee that some customers preferred. And going deeper on this, a kcup packer usually need a very good expensive grinder machine to do the grinding, but with EXPAK filter that never breaks, even with a entrance burr grinder is able to do a finer grinding and pack into kcup without any problem.

Is ground coffee cheaper than K Cup?

- Yes it is, but kcup is more convenient. There is a report that we found out is a 32-pack of K-cups costs $15.18 (or $0.47 per pod) whereas a 12-ounce bag of the same ground coffee only costs $13.15 and gives you enough to make 62 cups of coffee (about $0.21 a cup). This means it’s more than twice as expensive to brew a quick cup from the Keurig, this is because the kcup producer need to be licensed and pay for this platform, and this is actually why they made the 2.0 system. But as we have the 2.0 lidding and cheaper kcups and flexible packing machines, more kcup producer come into this field and produce their own kcups, so that cost is going lower and it is same as easy and convenient to make coffee by each kcup in the kcup brewers.

K Cup coffee capsule packing material.

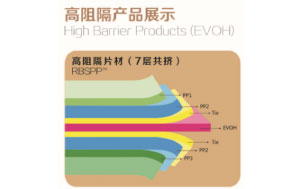

Empty K Cup outside cup

It’s Multi-layer co-extrusion technology, the outer cup made of 7 layers PP-EVOH-PP material can effectively isolate water and oxygen, and protect the aroma and flavor of coffee to the greatest extent.

What’s more, our kcup is recycled which meets the US standard requirements. We have a #5 PP recycled mark on our bottom, which you can see in every kcup.

Sometimes our customers will use empty kcup for soluble powder which can melt fast, like cleaning powder or hot chocolate. If you want to hold the inside filling material for a little bit long time to react with the water, we will suggest you to use kcup with filter product.

K Cup with filter welded inside

We have 2 types of kcup with filter products, one is our featured products and our best selling and most popular products: kcup with synthetic filter. If you want to produce ground coffee capsules, it’s your best choice.

- Synthetic filter:

- The non-woven fabric has the characteristics of more toughness and sturdiness, and it is not easy to be torn, it has good flow-rate, which allows the water to pass through faster, thereby avoiding over extraction of coffee hence makes good taste.

- Also, the characteristics of non-woven fabrics can also support finer grinding, so if your coffee grinds are very demanding, our products can ensure that the ground coffee with very finely ground can still have stable water and no breakage of filter.

- The internal capacity is about 45ml~50ml. Usually we can hold 10g~13g ground coffee in one kcup. It depends on your grinding degree of coffee.

- Also except the regular common 34mm depth filter, we can also provide 36mm even to the bottom type. You can tell us how many grams of ground coffee do you want to put and we can customize according to your requirement.

- Paper filter:

- The material of paper is more environmentally friendly, and the speed of water flow is slow, which is suitable for products that require more mixing time with water, such as tea, and some instant beverages.

- However paper is not as strong as synthetic filter, so we will not recommend you choose paper filter for coffee packing.

K Cup individual filter cup

As kcup with filter welded inside is actually an updated product by us, but some customers will still need the individual filter cup separately.

For this kcup individual cup, we have 2 different diameter size: 44.7mm and 44.9mm. We can send customers sample first for testing before our official order.

K Cup aluminum sealing foil lid/roll foil film

For kcup sealing, aluminum foil will be a common solution. Usually we will use precut foil lids, however we can also produce roll type film if your sealing machine needs.

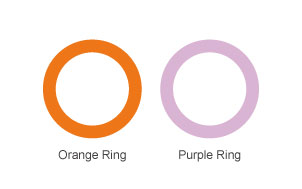

- 2.0 type with purple/orange security ring:

- As we all know, Keurig has upgraded its own 2.0 coffee machine, requiring that the sealing film of kcup must have 2.0 security ring printing, this 2.0 ring contains a special Light Sensitive Ink, and the coffee machine can work normally only if it can be sensed by the coffee machine. Otherwise, there will be an ’Opps!’ on the coffee machine screen and it will refuse to work.

- So if your target market is the North American market, your kcup sealing foil lids must have a 2.0 special identification ring.

- We can provide both purple ring and orange ring for the 2.0 type foil lids.

- 1.0 type without security ring:

- If your aim market is not north-America, such as Korean market, then you can choose the 1.0 type foil, both precut and roll film we can produce. You can do your customized designs more freely without the 2.0 security ring’s limitation.

Conclusion:To sum up, if you want to produce coffee capsules for the North American market, please choose kcup with synthetic filter+2.0 type foil; if you produce coffee capsules for other markets, please choose kcup with synthetic filter+1.0 type foil; if you produce tea capsules or other instant product capsules for the North American market, please choose kcup with paper filter+2.0 type foil; if you produce tea capsules or other instant product capsules for other markets, please choose kcup with paper filter+1.0 type foil .

Packing material FAQ.

How to choose the suitable kcup?

- You need to confirm your solution first: if you want to pack coffee just use our ready kcup with fabric filter, if you want to produce soluble then you can choose empty kcup as no filter inside is needed. If you want to pack tea, you can use our kcup with paper filter which can make a stronger tea.

How long is the shelf life?

- The shelf life can be over 18months, barrier type material can keep the coffee aroma for a long time to keep the coffee fresh.

What are the advantages to purchase from EXPAK?

- We have more flexible MOQ to support beginners, and competitive price as real manufacturers.

- We are supplying over 100million kcup and lids every year since 2010 so you are choosing a safe solution.

- What’s more, we also offer the packaging machine solution so could combine the packaging material as complete solution, this makes it easier and more convenient solution for people want to do a fast ready to run project. and when the business grows we also offer financial support to help the customer grow bigger with better cash flow , for example, 50% of the deposit + 50% of the balance will be settled within 60 days from the bill of lading so you could have the materials to pack ad sell the kcups and then pay for the material bills.

What kind of quality assurance do we provide?

- We have more flexible MOQ to support beginners, and competitive price as real manufacturers.

- We are supplying over 100million kcup and lids every year since 2010 so you are choosing a safe solution.

- What’s more, we also offer the packaging machine solution so could combine the packaging material as complete solution, this makes it easier and more convenient solution for people want to do a fast ready to run project. and when the business grows we also offer financial support to help the customer grow bigger with better cash flow , for example, 50% of the deposit + 50% of the balance will be settled within 60 days from the bill of lading so you could have the materials to pack ad sell the kcups and then pay for the material bills.

How to place an order?

- For kcup, choose the right filter of kcup, then we arrange sample for you to test and confirm, you can contact us anytime for inquiry or WhatsApp/skype message. We have enough standard kcups in stock over 2,000,000pcs. If you need customized depth of filter such as 36mm, 10 days leading time will be enough for us.

- For foil lids, first choose the orange or purple security ring, then provide us your lid design usually in AI format. Even if you don’t have, just send to us your logo and details like pantone colors etc. our design team can make it for you and send you the file, named “proof”. Once you confirm the proof, we can start the order for lidding plate preparation and produce the lids.

How to deal with the shipping?

- We offer flexible ways to deal with the shipping, usually as FOB if you have your own familiar shipping arrangement party. If not, CFR is preferred as we have good partners to reach fair price for sea freight. We need to confirm your quantity of kcups first, then we will calculate the weight and volume. Your destination sea port/airport/receiving warehouse address is needed if you are doing more than FOB, like CFR/CIF/DAP/DDP.

How to choose a reliable kcup packing material supplier?

- Company introduction, reputation, experience, certificate, brand, quality and materials feedback are important elements to consider. You can find ours in our website ‘About us’ Section. What’s more, in nowadays, online deal records will also help you to choose a more welcomed supplier, such as ALIBABA business records.

- On the other hand, we have professional technology in this business to control well. We are the real manufacturer of kcups and we can offer reasonable price and stable reliable quality. We also cooperate with experienced foil lids factory supplier directly for more than 10 years, which guarantee the quality and stable solution for sealing and packing.

How the kcup packing materials will improve my business?

- First, choose Kcup way can sell your coffee with more additional value than traditional packaging like coffee bean or ground coffee in bags.

- Secondly, EXPAK kcup and lidding is easier and cheaper. The cup is with filter ready solution so it is easier for kcup producer work with and this type kcup could allow the kcup packing machine work faster and more stable. Also the China made 2.0 lidding is cheaper and could save you every penny in this business.