2022 Upgraded Nespresso Pod Packaging Line

Nespresso Pod Packaging Line fulfill automatic operating and update with Euro Standard.

Constantly running for 17000 pods per hour.

Introduction

Expak CP5006 Nespresso capsule filling and sealing machine.

Additional information

| Suitable for | Nespresso |

|---|---|

| Speed | 240-300cups/min |

| Filling type | Servo motor driven auger filler |

| Filling accuracy | ±0.15g |

| Sealing type | Pneumatically driven heat and seal, Omron precise temperature controller |

| Voltage | 220v 50/60hz—3PHASE (by customer) |

| Dimension | 3500 mmX1050mX2062mm |

| Weight | 1500kg |

| Certification | CE, ISO Compliant |

Products Details

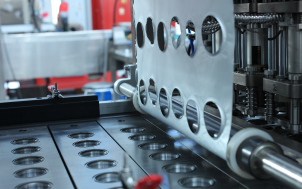

- The Six Lane Nespresso Pod Packaging Line are designed for large output for 18000 cups per hour.

- We can give a complete solution, filling machine connect with carton packer.

- Packaging line made of stainless steel SS304, Alarm system and broadcast system.

- Nitrogen Flush, UV light ensure aroma of ground coffee.

There are two methods to load capsule:

Vertical way and Horizontal way.

Vertical way is suitable for stacked type like Aluminum Capsule.

Horizontal platform matches a vibrator to forward unstacked capsule.

Horizontal Way to load cups & Vertical Way to load cups.

Two ways also assembly a set of electronic inductor to detect amount of cup.

Detection system, no cup without filling, foreign body detection alarm.

Dosing/Filling Station.

Tamper and Clean Station.

Punching Station and First Sealing.

Second Sealing Station.

Take out Packed Capsule.

2022 Nespresso Pod Series Packaging Line can compatible all the Nespresso Coffee Machines.

Filling Station

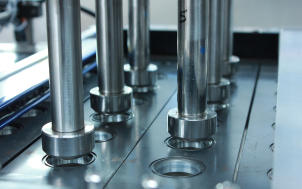

Six compressed filling head make top of cup with cleanliness.

Twin augers volumetric unit with a servo motor to ensure accurate and stable filling during high-speed augers rotation.

Two agitators in the hopper in order to coffee on a flow condition constantly and average.

We assembly a Cone-shape hopper made of SS304 Food Grade. And consider from the perspective of operator, we build a small plexiglass window to check situation inside and an induction can detect amount of coffee.

Operator could set and adjust weight separately look through the feedback on the SCHNEIDER controller.

And operator has an assistant which is “broadcast” alarm system when material is lacked.

Tamper and Clean System

After the filling station, coffee sometimes will remain a little around the cup, and ground coffee is not in flat level.

So the Tamper works and make the pressure of coffee granule in the capsule nearly equal.

Clean system will suck the coffee and some dust around the coffee edge.

Punch Station and First Seal

This station is for creating an aluminum or laminated lid that will cover the opening of capsule.

The servo motor controls the film pulling and unwinding, and at the same time the unused film is pulled to cut down and the used film is collected. The roll film mechanism realizes this complicated process. Lid will land the upper and center position of capsule.

While the heat copper head follows the cut blade and finishes the first sealing. (pressure and heat temperature can be adjusted).

Second Seal

After punching and preliminary seal, there would weld and sealing to guarantee the tightness perfectly.

Take Out Packed Capsule

Manipulators grab good ones and reject unqualified capsule.

Good ones are placed on a convey belt which between in a weight rank that you set.

Unqualified that less or over the weight you set would drop into a trash box below the machine with the capsule module running.

- Humanized solution

We are alarm system which is a broadcast connect with PLC when fault happen. So operator can be informed.

- Four sets of induction devices

First is on horizontal platform for detecting if cup is running out. (also fit to vertical way).

Second is after cup loading to detect there is something on the running mold.

Third is after cup loading to detect if there is a cup, no cup no filling.

Final one is after a station of lid drop. No lid no sealing.

- Nitrogen Flush

Nitrogen Flush through production, including hopper (container for ground coffee).

Want to know how to pack 10 pods in a carton?

Contact Us Immediately!