COFFEE PACKAGING EXPECT

WE GIVE YOU A ONE-STOP SOLUTION, WANT TO TOUR TO OUR MANUFACTURE?

CONTACT US RIGHT NOW!!!

OUR SERVICE

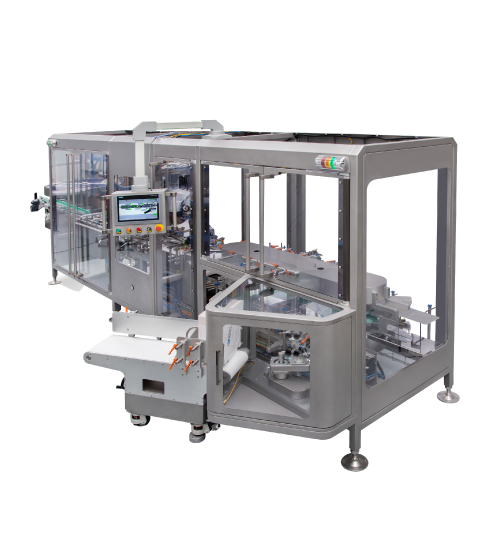

Full Mechanical K CupCoffee Capsule Filling Machine

at least 180 fill/minute

stand-alone K-cup cartoning machine

Tempore, ultrices morbi accusamus eos

Kcup with synthetic filter

Kcup with synthetic filter: PP laminated with EVOH inside, 7 layers barrier type material

For more products, click the button below!

WHAT MAKE US DIFFERENT

Advanced Technology Solutions

We leverage cutting-edge technology to deliver precision-engineered machines that ensure efficiency and reliability in every production cycle. Our equipment is tailored to meet diverse capsule sizes and packaging requirements with ease.

Comprehensive After-Sales Support

Our commitment doesn’t end with the sale. We provide unparalleled after-sales support except remote assistance such as phone call, Whatsapp and online remote controlling system, also including: On-Site Installation and Training: Our experienced engineers with US visa, are available to travel to countries include USA for machine setup.

Quality Assurance Excellence

Quality is ingrained in everything we do. Our stringent quality control measures guarantee that each machine meets international standards for durability, performance, and safety. We use only premium materials and components to deliver machines that exceed expectations.

Frequently Asked Questions

We have dedicated to coffee capsule filling machines, and cartoning machines for secondary packaging. Also include some customzied packing machine and solution such as variey pack for kcups, gusset bag filling and sealing machines so on. Also provide additional packing material etc.

EXPAK takes into account the needs of different customers and development stages. The production capacity of our coffee capsule filling equipment ranges from 50 to a maximum of 360 cups per minute, which is equivalent to 3000-21600 cups per hour. They are available for precut lid placement or online roll film cutting.

When designing the machine, we have already taken this into consideration. The design is all detachable and easy to clean, applying maintenance-free or high quality parts to achieve less frequent maintenance and upkeep. We have developed a maintenance and upkeep manual specifically for the filling machines so each client could understand and how to maintain their equipment.

What we provide are automatic machines, with a touch screen interface that allows the operator to control a single unit to run or simply press the “RUN” button in auto mode.

We offer two styles of machines for customers to choose from. One is a linear type, providing better accessibility, while the other is a rotary type, with a compacted size. The choice depends on each customer’s factory space and requirements. Each type of machine is fully functional and can be expanded with optional features.

Double Heat Seal (seal by two steps for better sealing)

We apply two heat seal stations to eliminate unqualified products. For k-cups, a curved seal is recommended for the secondary heat seal. We recommend a curved seal: The curved seal is stronger, creating a circle that presses the lid melted into the cup’s plastic material. While the aluminum film is sealed, it is engraved into a circular dent on the cover to ensure complete closure.

We have installed the nitrogen flushing system which a standard function on each machine. Inject nitrogen from empty cup loaded to heat seal. Even flush nitrogen to coffee hopper when coffee is refeeding to keep good aroma. Residual oxygen up to 1%.

Of course we do good sales support. Actually, this is what we always focusing on as well as providing quality machines. This should be viewed in three parts.

1. All filling machines for single-serve pods are fully assembled and ready, and we will run this machine to guarantee it works perfectly before shipping it out. When you receive it, you just need to hook up electricity and compressed air.

2. We could send engineers to customer site for set up equipment. We also have two engineers with US visas who stay in the states for coffee capsule production installation and training.

3. We could speak English, and the machines are made with an English interface for daily support. We use WhatsApp and iPhone iMessage like FaceTime to communicate, offering great service to help our customers. This is the best part we are proud to tell; we overcome the time zone difference for each customer in the world, and many nights we help our customers fix accidents on machines.

Sure, the machine comes with CE and ISO certificates. And door opening system for keep operator safety on every machine.

Although the lead time varies for different machines, the overall delivery time is between 50 and 90 days after we confirm the deposit and samples arrival.

Call us for A Manufacture Tour

We will online take you to our factory,

View what you interested in.